Innovative. Robust. Cost-effective.

We understand the importance of aligning with our clients' goals, and we work meticulously to ensure that every project hits the mark, transforming and revitalising land with a meticulous touch. It's this dedication to high standards that makes us the partner you can count on project after project no matter what problem you encounter.

Here are some of the many ways we can help:

Asbestos in soils

The widespread historic use of asbestos in the built environment means that asbestos impacted soils are found on a variety of sites. Not just typical post industrial land.

Whilst Asbestos is a highly emotive issue, the contaminated land industry has well developed and practical solutions for managing this issue.

Our solution:

Jackson Remediation have managed hundreds of thousands of tons of asbestos contaminated soils. We are experts in this area and have the ability to design and deploy complete solutions that are both robust cost-effective and compliant with the Control of Asbestos Legislation and the HSE notification system.

Piling through contamination

Jackson Remediation understands the important difference between "remediation" and "decontamination." According to the rules for contaminated land, the former is required. This means that after robust risk assessment, there are many occasions when residual contamination may safely remain on site underneath the construction make up of new buildings. However, this approach might lead to a situation where potentially impacted soils may be encountered by follow on ground workers or Piling contractors.

Our solution:

Jackson Remediation has ample experience of mitigating this risk. By applying robust health and safety measures for the following contractor, along with practical solutions for arising management, we aim to provide common sense solutions that allow our clients to employ the correct specialists to complete foundation and groundworks with the minimum of fuss.

Obstructions

Many post-industrial sites are found to be littered with inground obstructions, such as historic foundations, basements, tanks, tunnels, plant rooms, and even bombs shelters.

Our solution:

Jackson Remediation has experience of all kinds of inground obstructions. By working closely with our clients, we develop an appropriate scope of works to strike the right balance between expenditure and practicality. Typically, we agree a specified "obstruction-free thickness" from the finished level down. This gives the client confidence that follow on trades such as utilities or ground workers will be working without impediment.

In piled areas, we clear pile locations specifically, or map obstructions where it may be cheaper to relocate piles than to undertake the removal of a specific deep obstruction. At all times, we take a clearly communicated risk and responsibility that we seek to narrow in consultation with our clients in a collaborative manner. The upside of a heavily obstructed site is often that this generates a good source of hard material for recycling and reuse on site, or cost-effective disposal offsite where there is a material surplus.

Unexpected contamination

As is commonly required by contaminated land planning conditions, Jackson Remediation maintains a brief for unexpected contamination during all works. Our experienced and technically qualified on site staff carefully record these changes so that suitable risk management actions can be taken. We also provide site specific briefings for all site staff, so that everyone knows what to expect and how to report any issues

.

Our mobile treatment permit deployment documentation always allows for the eventuality that unexpected conditions are encountered and clearly sets out a management procedure to avoid disruption to the overall project.

Our management of unexpected conditions for which we generally take on board the full ground risk, reflects our knowledge based approach to dealing with complex Brownfield sites.

Hydrocarbons in soils

Jackson Remediation has extensive experience of managing hydrocarbons in soils. Whether managing degraded, diesel impacted soils or very high concentrations of aromatic PAHs, we rely upon our technical expertise and practical experience to deliver robust solutions.

We have a successful track record of undertaking field trials to determine the very best/most economic solution. Jackson Remediation has successfully deployed, bio-remediation, bio-piling, chemical, oxidation, stabilisation, and bio-augmentation to achieve the site specific assessment criteria across a number of sites.

We go above and beyond simply meeting the site specific assessment criteria, which include reliability, demonstrably, timescales, environmental effects, and the often overlooked geotechnical performance of the remediated soils.

Groundwater contamination

Our extensive experience of affirmative, groundwater remediation means we are highly focused on the performance criteria that has to be met. Unless carefully managed, the regulators' expectations may not conform with the method and timescales that must be practically employed under a remediation contract.

We often seek method based or multiple endpoint approaches to groundwater contamination. Starting with the end in mind, we can then design robust solutions which often work in concert to deliver the agreed specification.

Jackson Remediation has employed a number of groundwater remediation technologies including total fluids recovery (pump and treat); LNAPL removal via dedicated skimming; and DNA PL removal which employs emerging technologies such as the NT system. We have also addressed various dissolved phase issues by use of slurry walls, permeable, reactive, barriers, and a variety of proprietary compounds injected into the aquifer.

We have no “pet “ technology and our solutions are always informed by a careful conceptualisation of the problem.

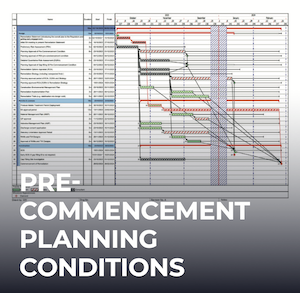

Pre-commencement planning conditions

Where our clients may be unfamiliar with the typical phased process associated with contaminated land and remediation, Jackson Remediation can act as as advisor at this early stage to help walk our clients through the necessary steps to get a project on the ground.

In addition to advising on the necessary operational permits and consents, Jackson Remediation is highly focused on the specific planning conditions that may require discharge prior to commencement on site. Full details of these conditions and how JacksonRemediation works with our clients to assist can be found on the Remediation Project Lifecycle page.

Landfill

As the availability of more traditional land for redevelopment is squeezed, more of our clients are exploring the possibility of redeveloping on either old landfill or land that has been subject to landfill. From an academic point of view, much of the material that has been landfilled, even in domestic type landfills, may be suitable to be processed into ground forming materials, e.g. the daily soil cover that may have been applied on landfills could be recovered and reused.

Jackson Remediation has practical experience of the challenges associated with landfill recovery from a physical processing perspective, understanding water/Leche management requirements, estimating accurately the reusable content, and having a good understanding of the permit requirements surrounding this activity.

Gasworks waste

Old gasworks are our bread and butter. Jackson Remediation has worked on gasworks redevelopments for 25 years and has a profound understanding of the challenges presented by these sites.

One of the key challenges of the redevelopment of old gasworks is often the presence of historic buried gasworks waste. These typically include tars, liquors, spent oxides and impregnated/contaminated timber slats.

Jackson Remediation has successfully recovered and remediated on site some of these materials, but also recognises the practical limitations as to what can be achieved by on-site remediation methods. Consequently, we have developed a network of specialist waste management options for even the most recalcitrant and difficult waste in a cost-effective manner.

Waste classification

Often the most significant cost element of Brownfield read development may be the cost of offsite disposal of surplus materials. Jackson Remediation are experts in waste classification in accordance with WM3. This allows us to accurately quantify and map the different types of waste that may be generated from a development.

Our expert knowledge also allows us to scrutinise classification and minimise overclassification of waste which in turn can generate significant savings to the project.

Fundamental to our ethos is that we pass the savings on transparently to our clients and ensure that this is communicated from the outset.

Material management

When presented with an enquiry, one of our key focus areas is to understand the necessary cut and fill required to deliver the site as per the client's specification.

Jackson Remediation employs specialist software and estimating tools to determine the overarching cut and fill as we are acutely aware that a significant cost element associated with the project will arise from the export or even import of material where there is not a suitable balance.

Jackson Remediation has an excellent track record of scrutinising cut and fill plans and the necessary design of the scheme to mitigate and minimise any offsite disposal costs. Counterintuitively, we will seek to preferentially retain on site the more impacted material (in accordance with any approved remediation strategy), and remove from site the lower cost less impacted material (such as broken or crushed concrete). We successfully deploy stabilised pile mats to maximise on site the reuse of soils/recovered fines. We do all of this in full accordance with the project materials management plan (MMP) that we draft ourselves and get independently verified.

Stabilisation and solidification

Stabilisation and Solidification (S/S) is a routinely deployed technology used to great effect by Jackson Remediation to address a wide variety of contaminants. Where bioremediation or chemical oxidation may not be effective and off-site removal simply too costly; S/S is proven to effectively lock- up mobile contaminants (even coal tar) and also deliver geotechnical improvement. We undertake in-house mix designs and trials to identify the most cost-effective solution and operate both in-situ and ex-situ methods. S/S is often employed alongside a materials management project, maximising reuse on-site and often being incorporated as part of a semi-stabilised pile mat.